Additive Manufacturing Methods

3D Screen Printing

Powder Bed Fusion

Binder Jet Printing

Directed Energy Deposition

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.

Additive manufacturing (AM), often colloquialized as 3D printing, has begun paving the way for a new generation of production capabilities in various markets. Initially introduced as a game-changing innovation in polymer prototyping, the additive manufacturing industry is now a go-to for manufacturing intricate components with small geometries from some of the hardiest engineering materials available.

Elmet Technologies (formerly H.C. Starck Solutions) has invested heavily into new AM technologies to accompany well-established refractory metal and alloy manufacturing capabilities. These two branches of our business coincide to enhance the range of products and services offered to the additive manufacturing industry overall.

Elmet Technologies (formerly H.C. Starck Solutions) has powder feedstock with tailored properties perfectly suited for the additive manufacturing industry. Our core competencies of tungsten (W), molybdenum (Mo), tantalum (Ta), and niobium (Nb)—in pure and alloyed forms—ensure our customers receive only the highest quality materials.

Our innovative powder manufacturing technology coupled with our vertically integrated supply chain and metallurgical expertise ensures the highest quality materials for demanding applications and environments. Our advanced technological processes enable us to customize our refractory metal feedstocks to precise requirements achieving outstanding material properties and optimum performance for additive manufacturing.

Elmet Technologies’ (formerly H.C. Starck Solutions) powders are specifically designed to meet the demanding requirements of the additive manufacturing industry. Their properties exceed traditional production specifications and offer:

Our customized alloy powder product portfolio includes:

We continuously develop new materials and methods and are ready to support your unique requests.

Elmet Technologies’ (formerly H.C. Starck Solutions) refractory metal 3D printing solutions support our customers in all key end markets and enable them to benefit from the unique advantages of AM. Industries currently served include medical, aerospace, industrial, nuclear, and defense. We continuously broaden our portfolio and work on innovating and designing parts for applications in markets that have not previously utilized refractory metals. Our promise of highest quality and optimal performance make us an ideal partner for even the most critical application areas of AM refractory materials.

Elmet Technologies (formerly H.C. Starck Solutions) provides high performance AM solutions for critical applications in aerospace and defense industries including propulsion, ballistics, and warheads. The reach of AM in end industries is expanding daily. Elmet Technologies’ (formerly H.C. Starck Solutions) constant research into new applications and materials allows us to actively participate in the design of future solutions.

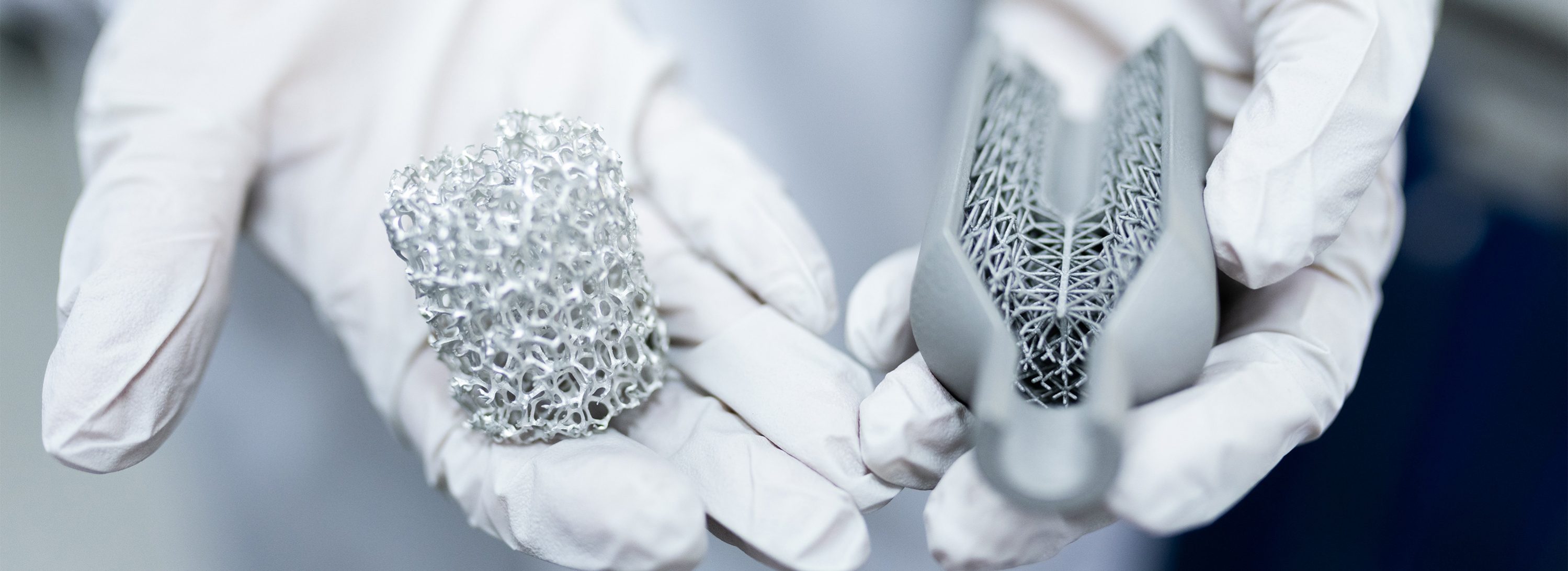

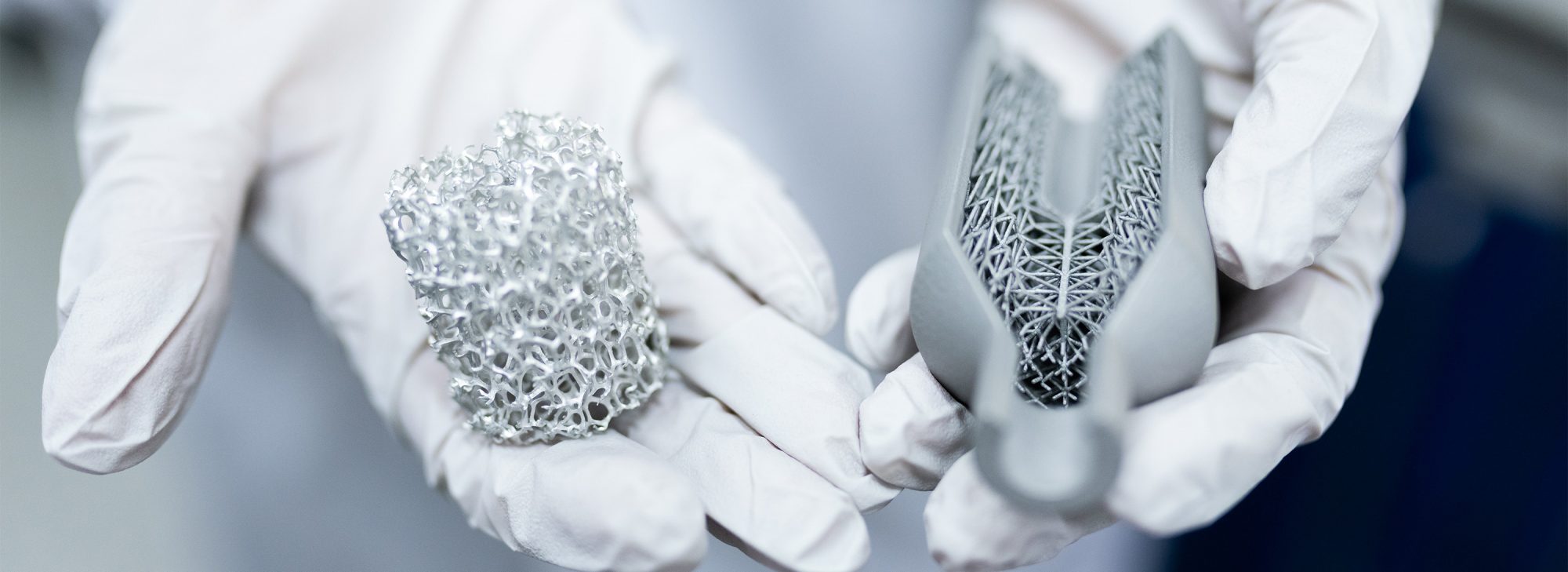

AM offers definite performance advantages for various medical applications in its ability to form porous structures to enhance bone osteointegration, tailor material properties to enhance implant design, and reduce overall part mass.

The corrosion resistance, durability, workability, and heat transfer properties of Elmet Technologies (formerly H.C. Starck Solutions) materials make them ideal for challenging applications in the Chemical and Pharmaceutical industries. In addition, today’s demanding applications in heat treating, sintering, brazing, annealing, metalworking, and other thermal processing areas require innovative AM refractory metal product solutions.

Additive manufacturing technologies encompass several distinct manufacturing techniques, including powder bed fusion and directed energy deposition.

Since the introduction of AM, a large variety of process technologies have been developed, and no single method fits all applications. Elmet Technologies (formerly H.C. Starck Solutions) works closely with its customers and partners to select the correct feedstock and method that will provide the most value to any given application.

We provide the expertise to select the best material and method for each application, maximizing customer value by balancing cost vs dimensional accuracy and part performance.

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.