Applications

Market Segment

Materials

Applications

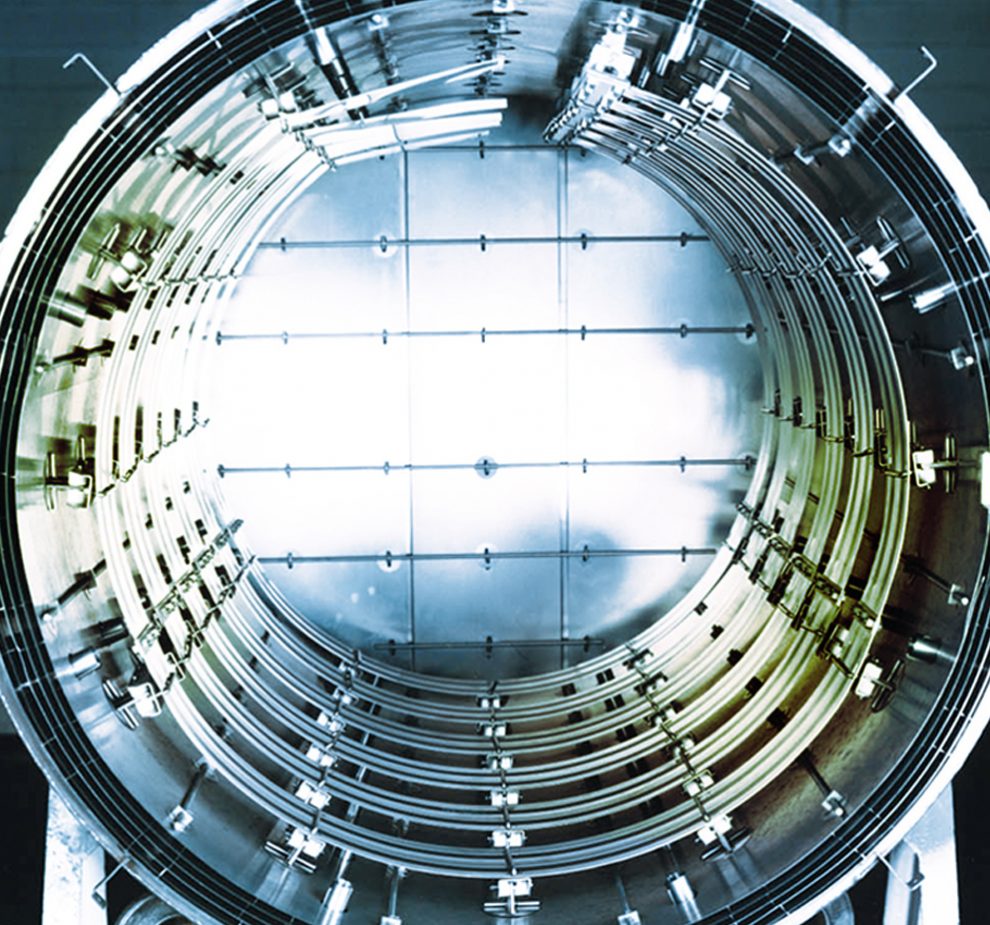

Hot zones are used for various high-temperature industrial processes, including vacuum heat treating and sinteresting, hot isostatic pressing, and crystal growth. These are useful processing techniques for metals with high-melting points, such as titanium alloys, silicon nitride alloy composites, and zinc selenide for creating components, metal sheets, and castings. Hot zone grown sapphire is widely used for optical applications, owing to its excellent hardness and good transparency when polished.

Market Segment

Hot zones and the manufacturing techniques they enable are used in a variety of industries, including aviation and defense, the electronics and semiconductor industries, and optics. All of these are very demanding applications that require excellent metal purities, and refractory metal hot zones help avoid contamination in the furnace and ensure better quality vacuum conditions.

Materials & Specifications

Hot zones often have to be customized for a particular application to achieve the desired manufacturing result. The exact hot zone designs are very demanding and this is why the Elmet Technologies (formerly H.C. Starck Solutions) molybdenum and tungsten materials and fabricated products are ideal for use as furnace components and fixtures.

Do you need custom or standard parts for hot zones in your furnace? Fill in the online RFQ form to see how Elmet Technologies’ (formerly H.C. Starck Solutions) extensive expertise in the design and supply of high-temperature furnace components can improve your production. Or, contact our Customer Support and Engineering Team to discuss your particular application and benefit from our well-trained engineering and design teams to find the right solution for your process.

Related Brochures

Request a Quote

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.